INSPECTION OF HEAT EXCHANGERS, BOILERS, CONDENSERS AND AIR COOLERS

- Técnica ECT ( Eddy Current Testing)

- RFT (Remorte Field testing)

- NFT ( Near Field testing)

ADVANCES NON-DESTRUCTIVE TESTING SERVICES

IMPROVE DE PERFORMANCE OF YOUR PROCESS

- Keep your heat exchange bundles in good condition, prevents incidents and unexpected plant shutdowns. Reduce costs and operate at maximum capacity.

- Inspection Service of Heat Exchangers bundles and detection of defects in Ferromagnetic and Non-Ferromagnetic Tubes of Heat Exchangers, Boilers and condensers.

- Our comprehensive inspection and diagnostic service includes a complete scan of 100% of the condenser tubes, in a notably reduced time using ECT (Eddy Current Testing).

- We provide advanced technology from Zetec and trained personnel with extensive experience to inspect tubular bundles in plant stops, achieving a conclusive diagnosis of corrective and predictive maintenance in a short intervention period.

ADVANTAGES OF BUNDLE INSPECTION SERVICE

Provide accurate information

Getting the actual condition of the bundle in every tube inspected, helps to generate a significant operation improvement, reducing operational risks, improving heat exchage efficient and extending the plant stop period safely.

Technical report

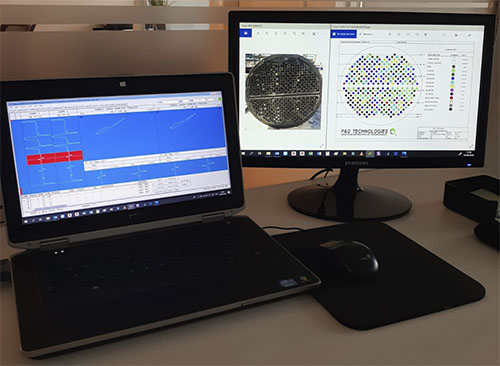

Get a fastest report just in time during plant stops, through our web application SIGMA and our online data analysts. Plan your plant stop, reducing shutdown times.

Comparative results technology

Analyze failure mechanisms, obtaining the necessary information to take corrective measures to eliminate or reduce unexpected plant stops.

Accurate prediction

Get an accurate remaining life tube prediction. Extend the in service life to it´s máximum capacity. Avoid premature or late re-tubed.

Reliability

Obtain efficient monitoring and greater operational reliability in the process, avoiding unexpected plant shutdowns.

Schedule

Extends bundle intervention periods, safely.

INSPECTION REPORT

The final report includes a detailed list of all the tubes, identifying the location of all the flaws detected in the length of the tube.

The list has an easy filtering system that allows you to access the results of each of the tubes, quickly and easily.

RESULTS

- Statistical graphics, observations, technical data of the inspected equipment and other data that allows the user to make a correct decision in its maintenance.

- The analyze report delivered by our company includes tube resistance calculations based on the flaws detected, among others observations made by our specialists in this type of inspection.

- With the SIGMA App, you will be able to track the condition of the bundles over time, for a better maintenance schedule.